Synthetic lubricants excel in summer heat.

Heat creates deposits. And deposits create problems.

Matt Erickson | DIRECTOR, TECHNICAL PRODUCT MANAGEMENT

While we rarely have triple-digit temperatures here in the Northland, drivers in the southern U.S. can easily see 100ºF (38ºC) and hotter throughout summer. Driving in these conditions stresses lubricants, especially when towing or hauling. In fact, our testing in Las Vegas showed that oil-sump temperature increased significantly throughout the day as the sun radiated more intensely off the asphalt.

Extreme heat causes oil to chemically break down faster, resulting in deposits and sludge. As a general rule, chemical reaction rates double with every 10°C (18°F) rise in temperature. Deposits can form throughout the engine, causing issues. Excessive combustion-chamber deposits cause pre-ignition, which reduces engine performance and can damage the engine. Deposits also lead to ring sticking, which reduces compression and horsepower.

Signature Series is about Cleanliness

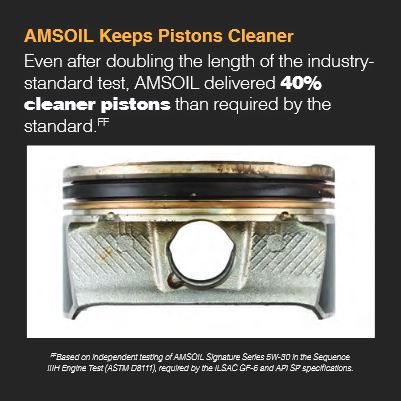

The ability to keep your engine clean when exposed to extreme heat is a main differentiator for lubricant performance. As the image shows, AMSOIL Signature Series Synthetic Motor Oil does an excellent job keeping pistons clean. We tested Signature Series in the Sequence IIIH test, which is required by the ILSAC GF-6 and API SP specifications, to demonstrate its ability to keep engines clean. The test subjects oil to 151°C (304°F) heat for 90 minutes – far hotter than your engine will ever get. Signature Series didn’t even break a sweat. Its viscosity was like that of new oil, and the pistons were still nearly spotless.

Re-using our USED Oil!!

To really test the oil, we told the lab to reassemble the engine and run the test again using the same oil. Even after doubling the test length, the oil still beat the standard by delivering 40 percent cleaner pistons.

These results were achieved because we formulate Signature Series to provide maximum protection. Among other features, it is fortified with potent detergent and dispersant additives that keep contaminants in suspension and keep them from settling in the engine. This is vital to everyone who cares about engine protection, but doubly so for motorists in regions where the temperature hits triple digits several months out of the year.

Maintaining sufficient viscosity to keep bearing surfaces separated is another concern when driving in the heat. While anti-wear additives are critically important, lubricant viscosity, or thickness, is the main mechanism to keep surfaces separated by an oil film.

Is your Oil Protected from Viscosity Loss? Very few are.

Heat, however, reduces oil viscosity, compromising wear protection. When oil loses too much viscosity (gets too thin), it can fail to prevent metal-to-metal contact, causing wear. Since lubricants generally thin as temperatures increase, we must formulate them to provide effective separation at the highest expected operating temperature.

The base oil influences a property called viscosity index (VI), which indicates the change in oil viscosity in relation to temperature. Oils with high viscosity indices do a better job maintaining viscosity in extreme heat. As you might expect, synthetic motor oils have higher viscosity indices than conventional oils, meaning they protect better when the heat is on.

In these situations, you can drive confidently and carefree knowing that you have AMSOIL synthetic motor oil in your engine. It has been tested in the field and in labs at temperatures far beyond those your engine will ever see. It’s proven to provide excellent protection, even at those extremes.