Break In Oil (SAE 30) Read the reviews! Best Break In Oil to season lifters and cam shaft areas with high ZDDP.

Amsoil’s conventional ZDDP Formulated Break-In Oil (SAE 30)

ZDDP Fortified Break-in Oil. Another Purpose built motor oil for engine builders.

AMSOIL Break-In Oil is an SAE 30 viscosity grade oil formulated without friction modifiers to allow for quick and efficient piston ring seating in new and rebuilt high-performance and racing engines. It contains zinc and phosphorus anti-wear additives to protect cam lobes, lifters and rockers during the critical break-in period when wear rates are highest, while its increased film strength protects rod and main bearings from damage. AMSOIL Break-In Oil is designed to increase compression, horsepower and torque for maximum engine performance.

“We get a lot of feedback on the AMSOIL break-in oil and I sell quite a bit here in the store. I to have used it in an air cooled Corvair with great results. In about 200 miles all issues with the fresh engine were solved. Even the price is just right!”

Quickly Seats Rings

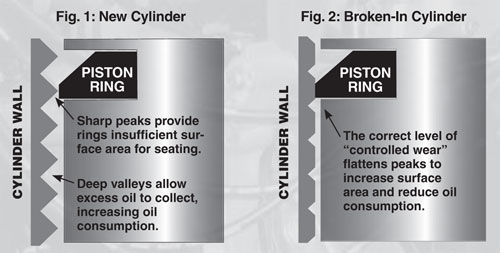

The primary goal during engine break-in is to seat the rings against the cylinder wall. Properly seated rings increase compression, resulting in maximum horsepower; they reduce oil consumption and prevent hot combustion gases from entering the crankcase. To achieve this, however, the oil must allow the correct level of controlled wear to occur between the cylinder wall/ring interface while maintaining wear protection on other critical engine parts. Insufficient break-in leaves behind peaks on the cylinder wall that prevent the rings from seating. The deeper valleys, meanwhile, allow excess oil to collect and burn during combustion, increasing oil consumption. Too much wear results in cylinder glazing due to peaks rolling over into the valleys and preventing oil from collecting and adequately lubricating the cylinder wall.

AMSOIL Break-In Oil’s friction-modifier-free formula allows the sharp peaks on newly honed cylinder walls (fig. 1) to partially flatten. The result produces more surface area for rings to seat against, allowing formation of a dynamic seal that increases compression, horsepower and torque (fig. 2).

Protects Critical Parts from Wear

New flat-tappet camshafts and lifters are not seasoned or broken in and must be heat-cycled to achieve proper hardness. During the break-in period, these components are susceptible to accelerated wear because they are splash-lubricated, unlike other areas of the engine that are pressure lubricated. AMSOIL Break-In Oil contains high levels of zinc and phosphorus (ZDDP) additives designed to provide the anti-wear protection required during this critical period.

Download and print the updated Data Sheet on the SAE 30 Break In Oil

Download PDFProduct DatasheetIncreased Film Strength

High-performance and racing engines often use aftermarket parts designed to increase torque and horsepower. The added stress can rupture the oil film responsible for preventing harmful metal-to-metal contact on rod and main bearings. The base oils in AMSOIL Break-In Oil provide increased film strength to protect bearings from wear.

APPLICATIONS

AMSOIL Break-In Oil is designed to effectively break in high-performance and racing engines requiring SAE 30 oil, helping maximize compression, horsepower and torque.

RECOMMENDATIONS

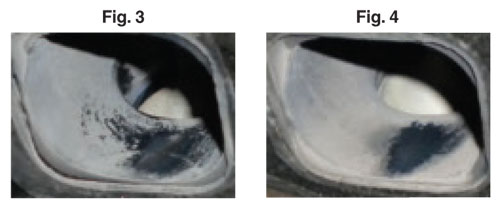

The engine builder’s or manufacturer’s break-in recommendations should be followed if available. Break-in period should not exceed 1,000 miles. When the engine is new, the exhaust ports will have a large area of oil residue (Fig. 3). As the rings begin to seat, less oil is passed and the oil residue area begins to shrink (Fig. 4). When the rings are fully seated and have formed a tight seal against the cylinder walls, no oil residue will be evident. Other common methods to determine if rings have seated include performing a leak-down test or horsepower measurements over time. Break-in duration will vary between engines. Afterwards, drain and fill the engine with an AMSOIL high-performance synthetic oil that meets builder or manufacturer specifications.

Buy & PricingHow is break-in oil different from regular oil?

Break-in oil is different from regular motor oil because, by design, it is supposed to allow the rings to wear down the peaks on the cylinder wall to form a good seal. Regular motor oil, in contrast, is designed to prevent wear.

Camshaft break in

Flat-tappet cams can wear out faster than their roller-cam cousins, especially in engines modified with high-tension valve springs. Worn lobes or tappets affect valve lift and duration, which reduces engine power and efficiency.

In extreme cases, increased pressure can remove material from the lobes and deposit it in the oil, where it circulates through the engine and causes damage. Using break-in oil helps harden the camshaft so it’s more resilient to wear.

As a rule of thumb, a good break-in oil should contain at least 1,000 ppm ZDDP. At AMSOIL, we take it a few steps further; our Break-In Oil contains 2,200 ppm zinc and 2,000 ppm phosphorus.

Break In Oil Product Reviews

100% happy

BEST BREAK IN OIL, PERIOD!

Great product

Highly recommend product

I am definately impressed! Great products!

Great product

This break in oil is great for new engines

Totally Recommend