AMSOIL TECH TALK

By Dan Peterson – Vice President of Technical Development

When motor oil exceeds its useful life or is affected by a mechanical defect, it most commonly becomes too thin to separate metal parts, too thick to pump or too acidic for continued use.

Too Thin

When oil becomes too thin, it fails to provide the required oil film thickness to separate metal surfaces. Different engine designs require different starting oil thickness, or viscosity. Viscosity at 100°C is one of the most highlighted oil properties and is a good indicator of adequate oil film thickness in an engine at operating temperature.

A number of things can cause motor oil to become too thin to protect engine parts. Excessive mechanical shear can thin oil to the point of causing issues with engine protection. As motor oil cycles through the engine, it is exposed to shear stress in the engine’s upper end, piston walls and bearings that reduces its shear strength. Continuous exposure to these conditions causes oil built with inferior shear stability to thin excessively, leaving critical engine parts susceptible to metal-to-metal contact.

Fuel contamination of the oil sump is another major cause of excessively thin motor oil. Both gasoline and diesel fuel are thinner than motor oil and, when mixed, the oil’s viscosity, film thickness and ability to separate parts are significantly reduced. While a small amount of fuel dilution is relatively common and does not have a material impact on oil life, excessive fuel dilution in mechanically compromised equipment is much more harmful.

Too Thick

When it comes to oil, although it may seem like “the thicker, the better,” oil that is too thick is just as detrimental as oil that is too thin. Excessively thick oil is a commonly discussed mode of oil failure.

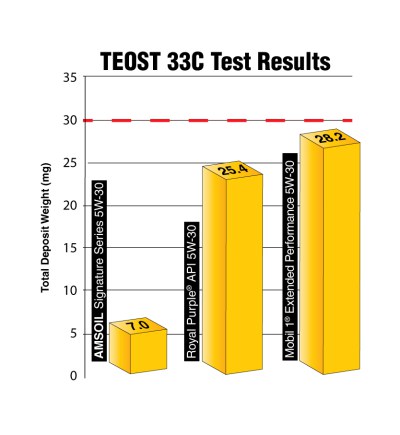

When oil becomes too thick to flow to engine parts, these areas are starved of oil, resulting in metal- to-metal contact that can lead to catastrophic engine damage. The precursor to sludge is oil that has become much thicker than its original design. The cause is a complex chemical reaction involving heat, combustion by-products and oxygen combining to create a chemical attack on the oil molecules. The resulting chemical reaction creates a much thicker substance that does not flow or protect as well as the original oil. When the reaction continues, sludge begins to form in areas of higher localized temperature and low flow. While some varnish is normal, sludge is a sign of excessively degraded oil that needs to be replaced. In order to inhibit sludge and varnish, the oil must resist attack by oxidation forces. Synthetic base oils have a much higher level of saturated molecules that inherently resist this constant bombardment. Additionally, antioxidants are added to either reduce the formation of free-radical oxidation precursors or soak up these precursors once they form.

Another cause of oil thickening, primarily affecting diesel oils, is excessive soot-loading in mechanically unsound engines. Diesel oil is designed to handle some soot contamination, but when the soot overloads the available dispersants in the oil, the oil thickens. The agglomerated soot particles reach a critical size and cause excessive wear commonly seen in diesel liners.

Too Acidic

Acids are a normal by-product of burning fossil fuels. Different fuel types, engines and combustion conditions create varying levels of acid formation. These acids, transferred via blow-by gases, are carried away to the motor oil. Motor oil is designed with a detergent that neutralizes these acids before they accumulate and cause engine damage. The detergent level is measured with a test called Total Base Number (TBN). This measure of alkalinity drops over the life of the oil and reaches a critical level when the oil can no longer consume the acids created by combustion. When TBN reaches a critical level, acids build up quickly and attack the surfaces most susceptible, including yellow metals and lead-lined bearings. Without correction, this condition quickly worsens and results in excessive chemical wear. Although less common, this failure mode can cause significant damage if left uncorrected.

AMSOIL synthetic motor oils are formulated to provide superior overall protection. They resist mechanical shear and viscosity increase due to oxidation while combatting harmful acids to help you maximize the performance and life of your engine.