Hydrostatic transmissions require advanced fluids

AMSOIL’s Hydrostatic Fluid has become a high demanded product with nearly no advertising. Accelerated word of mouth impressions works quickly in the landscaping industry. Especially when there are no other specialized products in such a void.

Professionals have zero tolerance for zero-turn-mower inefficiency.

Mike Nelson | SENIOR PRODUCT DEVELOPMENT ENGINEER

Landscape professionals, some of our best potential commercial accounts, rely on their zero-turn mowers to get work done on time and up to standards. When a crew member jumps on a mower and pushes the handles forward, he expects instant and predictable mower response. Anything else wastes time and reduces efficiency.

This is where you step in. AMSOIL Synthetic Hydrostatic Transmission Fluid (AHF) helps deliver smooth, responsive operation. To understand how, let’s look at how a zero-turn mower hydrostatic transmission works.

How a Hydrostatic Works

In most systems, hydraulic lines connect a variable-displacement pump to a fixed-displacement motor that powers one of the rear wheels. Moving the mower handle forward increases pump displacement and turns the motor that turns the wheel. The system offers infinite variability, meaning the mower’s engine can be running at 3,600 rpm, but wheel speed depends on how far forward the operator pushes the handle.

A typical hydrostatic transmission also uses a charge pump, which cycles new fluid into the hydrostatic loop to replace fluid that leaks through the pump cases. This provides the added benefit of cooling the pump and motor as new fluid enters the loop.

Variable-displacement piston pumps are the mainstay in zero-turns. They use a ring of pistons that ingest and compress fluid based on the angle of a swash plate connected to the control handle.

Some zero-turn mowers use what’s called a gerotor motor. They use a valve body to pressurize fluid between a rotor and stator, which causes the rotor to orbit. As it orbits clockwise, it rotates counterclockwise at a much lower speed. The rotor is splined to the output shaft to turn the mower wheels.

Preventing wear on key parts

Hydrostatic drives place specific demands on fluid, which is where you enter the picture. The gerotor motor in particular generates increased sliding forces on the splines. This requires anti-wear additives like zinc and phosphorus to form a wear-resistant barrier on parts to prevent scuffing and wear. Because these transmissions operate with extremely tight clearances under high pressure, they mechanically shear lesser-quality oils, reducing viscosity and changing the behavior of the machine.

To deliver maximum performance, we formulate AMSOIL Synthetic Hydrostatic Transmission Fluid with high-quality base oils that resist shear. In severe service, they maintain viscosity better than fluids that use viscosity modifiers to compensate for lower-quality base oils. They also resist oxidation in extreme heat better due to their uniform molecular structure. This provides more predictable performance while fighting harmful varnish and deposits inside the drive.

Tested beyond typical requirements

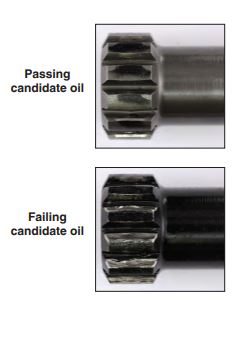

When developing our hydrostatic fluid, we tested various formulations in our mechanical lab. Our testing is designed to punish lubricants beyond conditions seen in the real world. We push them to the limit for up to 1,000 hours to see how the oil formulations and hydrostatic drives survive. Some of the wear-prone areas we see in these units are in the motors that drive the output shaft. As you can see in the bottom image, it’s evident when a test formulation fails to protect metal in this critical area. Wear like this leads to inefficiency and increased replacement costs.

Zero-turn-mower hydrostatic drives are ingenious systems that help workers cover a lot of ground quickly – if the fluid can protect against wear and deposits. Thanks to extensive testing, AMSOIL Hydrostatic Transmission Fluid delivers. It helps mowers and other equipment provide the smooth, responsive operation needed to get jobs done on time and up to standards. Make this a selling point when talking to prospects.