Hydraulic Power: Common Problems and Solutions

In the simplest terms a hydraulic power system consists of a sump, motor, pump, valves, actuators and hydraulic fluid. This combination can be configured into millions of applications to transfer power and reduce mechanical complexity. If properly maintained, hydraulic power systems offer exceptional reliability. If not maintained properly, repairs can be expensive, depending upon the application.

Signs of trouble

Telltale signs of hydraulic problems include noise, elevated temperatures and slow/erratic operation. Heat, air contamination and water contamination are the most common causes of poor hydraulic performance. The hydraulic pump is the heart of the system – and the most expensive component to replace. When the pump begins to wear, it can introduce debris into the system, causing downstream issues. Industry analysis indicates 80-90 percent of problems are the result of contamination or poor quality Hydraulic Oil from discount sources.

Heat degradation

Increased fluid temperatures can be the result of the system’s inability to dissipate heat. In most systems, heat within the fluid dissipates through the fluid in the reservoir and a heat exchanger. Heat can cause the fluid to thin, which prevents proper lubrication and may cause pump leaks, reducing pump efficiency and system performance. Further increases in temperature cause the fluid to oxidize (or, essentially, vaporize), which thickens the fluid and creates varnish and deposits. Fluid thickening further impedes its ability to cool and lubricate components and may cause deposits to form on components, restricting fluid flow.

Air contamination

Noise is usually related to air entering the system, which leads to aeration or cavitation. When air bubbles contaminate the fluid, it’s referred to as aeration and results in banging or knocking noises due to the compression and decompression of the air as it moves through the system. Air also causes wear due to the implosion of air bubbles under the immense system pressure. Erratic actuator movement is also often the result of aeration. When air is compressed in the system it causes increases in temperature, which degrades the hydraulic fluid and overheats the seals. Air can also cause damage due to lack of lubrication.

Cavitation can also be a source of noise and erratic actuation. Cavitation is the result of fluid vapor or air cavities within the fluid, which implode when compressed, causing a knocking noise. Cavitation causes wear, damaging components and contaminating the fluid with metal particles, which in extreme cases can cause mechanical failure.

Water contamination

Hydraulic fluid that has a milky appearance is a clear indication of water contamination. One source is condensation buildup on the walls of the fluid reservoir as a result of temperature changes from warm days to cool nights. Water contamination can also corrode the pump and other critical components, which can shorten component life. Water can also freeze, causing a host of performance and wear-related issues. Periodic fluid changes and draining of the water from the reservoir ensure water removal from the system.

Fluid levels, filtration and fluid quality

Maintaining the correct fluid level, using proper filtration and repairing any leaks are the first line of defense against excessive heat and contamination. Using the correct, high-quality fluid is also important.

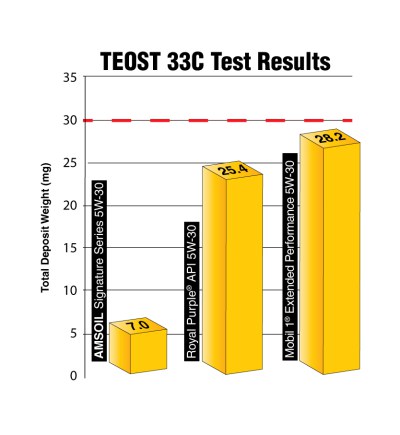

Synthetic hydraulic oils offer exceptional protection in extreme heat and cold while improving efficiency. Synthetics also offer improved resistance to oxidation as a result of heat. Fluids with oxidation inhibitors add even more resistance to heat. Fluids formulated with anti-wear additives help prevent pump and valve wear and provide additional protection in severe conditions. Lastly, anti-foam additives aid in releasing air from the system.

Check out the AMSOIL Line of Fluids in two groups for value and performance!

AMSOIL formulates a full line of synthetic hydraulic oils that help combat these performance issues, saving you time and money.