Viscosity breakdown

Lubricant viscosity affects wear protection, fuel efficiency and other critical areas of oil performance.

Matt Erickson | VP, PRODUCT DEVELOPMENT

Viscosity is one of the most important properties of a lubricant. Using the right viscosity oil is vital to providing your engine the best wear protection.

The real secrete to our formulations is after all the other additives are tweaked to maximize performance, we go back to the drawing board to put emphasis on viscosity retention. Watch your oil gauge from start to finish of the life of the oil and there’s the AMSOIL difference. Fighting off Viscosity breakdown! Let’s jump into the technical details of our products, so let’s dive in.

While viscosity is defined as resistance to flow, people often think of it as a fluid’s thickness. Lower-viscosity fluids are thinner and flow more readily than higher-viscosity fluids. That’s why water flows more easily than honey.

Lubricant viscosity influences the thickness of the fluid film that forms on metal components to prevent wear. Higher viscosity oils form a thicker fluid film, offering increased protection against

metal-to-metal contact. That being said, why not use 20W-50 in your car or truck instead of the 5W-20 or 5W-30 it probably takes?

Consider A Balance

Balance, that’s why. A lubricant with viscosity that is too high for the application requires more energy to circulate, meaning fuel efficiency suffers. The increased internal friction also increases heat, which accelerates chemical breakdown (oxidation). Plus, thicker lubricants don’t flow as readily at startup, especially in the cold, which reduces wear protection during cold starts.

Permanent viscosity loss due to mechanical shear can also affect protection. The intense pressure the oil bears as it’s forced between the cam lobes and tappets, meshing gear teeth and other components can shear its molecules, causing it to lose viscosity and fail to deliver the required

protection. Fuel dilution also reduces viscosity. This occurs when gasoline or diesel fuel blow by the piston rings and contaminate the oil in the sump.

Don’t second guess the desired viscosity

Engineers build engines, transmissions and other components to operate best and last longest using a lubricant of a specific viscosity. Newer engines, for example, are built with tighter tolerances and clearances. They require lower-viscosity lubricants to ensure the oil flows fast enough at startup to fill the bearing cavities and prevent metal-to-metal contact. That’s one reason many modern engines require 5W-20 or 0W-20 oil instead of the 10W-40 of yesteryear. Some Toyota* and Honda* engines even use 0W-16.

Viscosity is a result of choosing the right base oil combination. Base oils come in a variety of viscosities, and selecting the right combo is the starting point. Next, the viscosity modifier is chosen

to thicken the oil and ensure it meets viscosity requirements for both the cold-temperature requirement (the “W” rating) and the operating-temperature requirement (the second number).

Top-quality synthetic oils combined with high-performance viscosity modifiers result in oils that resist viscosity loss and chemical breakdown in tough operating conditions.

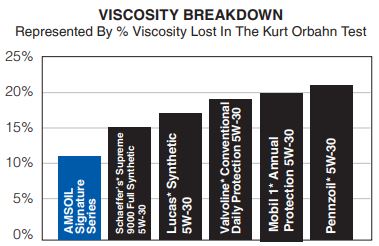

Using the right viscosity doesn’t matter if the oil doesn’t retain its viscosity despite shearing forces, extreme heat, fuel dilution and other conditions. As the graph shows, AMSOIL Signature Series Synthetic Motor Oil fights viscosity breakdown better than the competition,¹ providing superior protection of bearings, cams and pistons. It helps your engine maintain horsepower and deliver long life.

The ability to retain viscosity, and therefore provide excellent protection, is a great way to differentiate our products. Next time you have a potential customer interested in learning more about AMSOIL products, try explaining the importance of viscosity and how our products outperform the competition.