Why Does My Engine Knock? 3 Possible Explanations.

There are a few different reasons your engine might make a knocking, ticking or pinging noise. Let’s break each down and talk about what might be happening.

Engine knock, tick or ping?

One driver’s knock is another driver’s tick. Or ping. Still others compare the noise their engine makes to marbles rolling around inside a coffee can.

The spontaneous ignition of the air/fuel inside the cylinders is a common source of abnormal engine noise. While the description of the sound may differ, the circumstances under which it occurs are often the same – low-speed, high-torque conditions common when you’re accelerating.

Engine knock typically occurs during low-speed, high-torque conditions, like when you’re accelerating.

Say the clock has struck 5:00 and you make a bee-line to your truck and take off for home. When you mash the accelerator out of the parking lot, that’s when you hear your engine knock. Or ping. When you let off the gas, it goes away.

This is likely due to either pre-ignition or detonation. They’re effectively the same phenomenon, but they occur at different times.

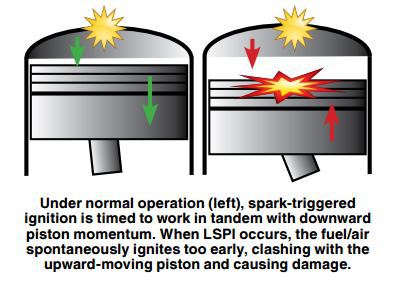

In a properly running engine, spark-triggered ignition typically occurs a few degrees before the piston reaches top dead center (TDC). This careful timing ensures the downward force of the exploding fuel/air mixture works in tandem with downward piston momentum, resulting in optimum efficiency and power.

That’s bad timing

Pre-ignition (and its cousin, low-speed pre-ignition [LSPI]) are abnormal combustion events that throw off this precise balance. Under certain conditions, the fuel/air can spontaneously ignite too early in the combustion cycle. Sometimes low-octane fuel is to blame, sometimes it’s deposits on the piston crown.

Detonation has the same effect, except it occurs after the plug fires.

Computers in modern vehicles can detect engine knock and compensate by adjusting engine timing. Though it saves your engine from destroying itself, performance and fuel economy can suffer.

Tick, tick, tick

Say your engine is ticking like a time bomb, especially in the morning when it’s cold. You likely have a valve-train issue.

Your engine uses intake valves to usher clean air into the cylinders and exhaust valves to kick spent combustion gases out. The valves open and close thousands of time per minute in a choreographed whirlwind of activity.

A finely balanced system of parts – rocker arms, valve stems, cam lobes, lifters – control their movements. The clearances between these parts, known as lash, can become loose (or sloppy, in automobile nomenclature). When that happens, all those moving parts clattering against each other can create a ticking sound.

It’s especially noticeable in the morning before the oil has had a chance to circulate throughout the upper end of the engine.

Many engines use hydraulic lifters, which use an oil-pressure-assisted plunger and spring to compensate for lash, helping ensure the system runs smoothly and quietly.

Proper oil pressure plays a big role in valve-train operation and noise. Low oil pressure can reduce the effectiveness of hydraulic lifters, increasing lash. This is most likely to occur with a low-quality conventional oil that thins at high temperatures, preventing the engine from developing good oil pressure.

If the rods are knockin’…

Rod knock is yet another possible explanation for your engine noise.

Your engine is built with a designed clearance between the crankshaft journals and the connecting rods. In a properly running engine using a good oil, the motor oil fills those clearances and prevents metal-to-metal contact.

But, let’s say you’ve been using a poor-quality conventional oil. At high temperatures, the oil thins and the fluid film weakens. The pressure between the crank journals and connecting rods squeezes the oil from the clearances. Now, metal is riding on metal, wearing the surfaces and widening the clearances. Eventually the clearances widen so much that you begin to hear the metal surfaces clattering against each other. Eventually, they’ll weld together and destroy the engine.

Quieting a noisy engine

This all sounds dire. But you can sometimes address pre-ignition by using a higher octane gas or by cleaning deposits from your engine.

Using a higher-quality oil that flows better in cold weather and maintains its viscosity when hot can sometimes quiet a valve-train tick.

Rod knock is the worst of the three. Once the clearances between the crank journals and connecting rods have widened due to wear, it’s just a matter of time before catastrophic damage.

In any case, visit your mechanic and take care of the problem before it gets worse.

The moral of the story is simply to pay a little more now to maintain your vehicle rather than spend a lot later to fix it. Use a high-quality oil that stands up to extreme heat and maintains correct oil pressure. Periodically clean combustion chamber deposits with a fuel additive, such as AMSOIL P.i.®.

Doing so can help keep your vehicle running properly and quietly for years.