Solving Next Generation Turbo/GDI Problems

These increasingly common features of modern engines heighten power and efficiency, but also present serious challenges to motor oil.

The push toward smaller, fuel-efficient, yet powerful engines has driven the development of several key technologies. Gasoline direct injection (GDI) and turbochargers are now common features of passenger cars and light trucks. By 2020, industry experts predict that nearly every new vehicle will feature GDI technology, and the vast majority will be turbocharged (TDGI). While these advanced technologies enhance performance, they also present serious challenges to motor oil.

Turbochargers: Bringing The Heat

An engine is essentially an air pump, and the more air it ingests, the more fuel it can burn – and the more power it can produce. Turbocharging has emerged as the favored choice of automakers to increase the amount of air their engines take in. Unfortunately, extreme temperatures come along with the increased power.

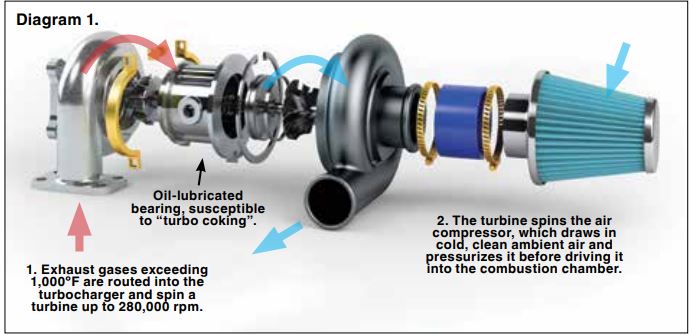

Exhaust gases commonly exceeding 1,000ºF spin a turbine which drives the compressor that draws ambient air used to pressurize the combustion chamber. The added oxygen combined with direct injection and advanced engine tuning helps the engine burn fuel more efficiently, boosting fuel economy. It also allows the engine to burn more fuel for increased power. Motorists enjoy the performance and fuel economy they demand, while automakers meet increasingly strict CAFE (Corporate Average Fuel Economy) requirements.

While it seems like a win-win situation, it’s the motor oil that gets the short end of the stick. The turbo’s center section contains an oil-lubricated bearing. The tremendous heat and stress turbos create can cause some oils to break down and form harmful bearing deposits, known as turbo coking. Over time, turbos can suffer reduced performance or fail altogether.

GDI & Fuel Dilution

Gasoline direct injection delivers accurate and rapid distribution of atomized gasoline. While traditional fuel-injection systems spray fuel into a manifold, GDI systems locate the injectors in the combustion chamber, which enables much more control over the amount of fuel injected and timing of fuel injection, improving combustion efficiency. Spraying the fuel directly into the chamber also provides in-cylinder cooling, which helps allow higher compression ratios, increasing efficiency. GDI engines use a mixture of 40 parts (or more) air to one part fuel during light loading, while traditional gasoline engines use a mixture close to 14.7 parts air to one part fuel. The 40:1 ratio means less fuel is burned during combustion, resulting in better fuel economy.

The major side-effect of this technology is the increased risk of fuel dilution. As fuel is sprayed into the combustion chamber, it can wash past the rings and down the cylinder walls, into the oil sump. Fuel dilution can cause a number of problems:

• Reduced oil viscosity interferes with formation of a durable lubricating film, inviting wear. Combustion-zone parts are especially prone to wear, including the pistons, rings and liners. Reduced viscosity also negatively affects the oil’s ability to function as a hydraulic fluid, which is critical in engines with variable valve timing.

• Fuel can wash oil from the cylinder wall, causing higher rates of ring, piston and cylinder wear.

• Reduced effectiveness of detergency additives limits the oil’s ability to guard against deposits.

• Increased oil volatility results in higher oil consumption, requiring more frequent top-offs.

• Accelerated oxidation reduces the oil’s service life and requires more frequent oil changes.

Maximum Protection

Advanced automotive technology, including turbochargers and gasoline direct injection, requires high-quality motor oil to perform and last as designed. AMSOIL synthetic motor oil enables modern engines to achieve their full potential and service life. It provides superior protection against extreme heat and the harmful deposits that can plague turbochargers and features high film strength to guard against accelerated wear.