Oil Analysis – Making Sense of Used-Oil Reports

Analysis of used oil provides insights into the health of the oil and filters as well as the equipment. While the benefits of analysis are clear, making sense of the report you receive can be a challenge. Unpacking the elements of a typical report is a great way to improve clarity.

Each oil analysis lab has a slightly different report layout and you should check with your analysis lab if you have questions specific to your report as they may not follow the exact order or explanations below.

Garbage in, garbage out

Getting the most out of your oil analysis reports starts with your sampling process. Oil analysis is a data-driven process that requires a set of data points over time to provide insights. Establishing a trend usually requires a minimum of three samples, and consistency is important. For best results, take samples…

- Under normal conditions or immediately after shutdown while at operating temperature

- At regularly scheduled intervals

- From the same sampling point within the engine

Most reports are divided into five major sections: (1) Comments, (2) Wear Metals, (3) Contaminants, (4) Additive Metals and (5) Viscosity, Contaminants & Degradation.

Comments

Most capable oil analysis labs have data analysts on staff to explain the results and, if necessary, make recommendations to rectify significant changes in the lubricant or the engine condition. Starting first with the comments section provides a road map to understanding the rest of the report.

Wear Metals

Wear metals are measured in parts per million (ppm). The source of these particles in most cases is related to engine-component wear. Results from wear metals can indicate if components in the engine are operating in a normal state, nearing failure or have already failed.

Common wear metals include iron, chromium, nickel, aluminum, copper, lead, tin, cadmium, silver and vanadium.

Contaminants

Knowledge of the conditions in which the vehicle is operating can help explain varying levels of contaminants. Excessive levels of dust and dirt commonly show up in this category and can lead to accelerated wear.

Common contaminants include silicon, sodium and potassium.

Additive Metals

Many of these metals are components within the oil’s additive technology. Molybdenum, antimony and boron are additives in some oils. Magnesium, calcium and barium are often used in detergent/dispersant additives. Phosphorous and zinc are used in anti-wear additives. Decreases in these metals can be an indicator that the oil’s capacity to protect is also diminishing.

Viscosity, Contaminants & Degradation

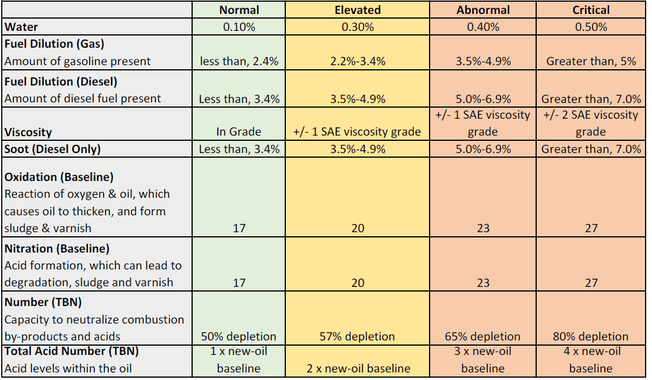

This section of the analysis shows changes in viscosity; common contaminants such as fuel, water and soot; as well as the degradation of the oil’s ability to neutralize acids. The following chart shows general guidelines for the respective attributes:

AMSOIL offers oil analysis services through an independent lab. For details, visit www.oaitesting.com.